PTFE convoluted-bore hose was designed to provide greater flexibility to fluoropolymer lined products. These hoses offer better ease of bending and a tighter bend radius than smooth-bore PTFE hose. Convoluted bore PTFE hose carried all of the benefits of smooth bore PTFE hose. First, is a low coefficient of friction, allowing excellent chemical resistance and compatibility to virtually any media viscosity. PTFE hose carries a very high temperature rating, from cryogenic conditions to well over 400 Deg. F. Like all PTFE hoses, convoluted bore PTFE hose had non-aging characteristics. It does not degrade and withstands continuous flexing, vibration and impulse cycles.

Our basic PTFE convoluted-bore hose is our TSV and TSV-B tape wrapped, low profile product. This hose has a high corrugation count for added flexibility and kink resistance. It is offered in natural white PTFE or static-dissipating black PTFE. Available with a variety of stainless steel or PTFE coated stainless steel end fittings.

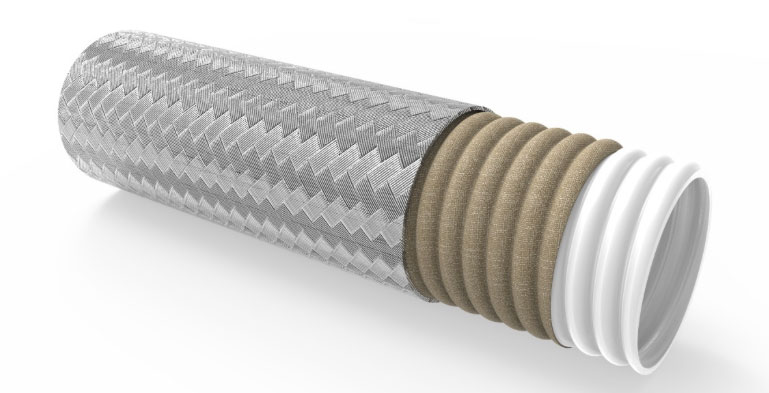

Unisource Series TSVO is our heavy-wall, flare-through style of PTFE convoluted-bore hose. It is intended to convey media without material entrapment. Large convolutions promote free-flow of media and is easy to clean. At the time of fabrication, the PTFE hose liner passes through the inside to the fittings and is then flared over the face of the fitting. All wetted surfaces are PTFE. An exterior stainless steel braid provides high pressure rating.

For conveying chlorine in tank car loading or unloading, in pulp and paper bleaching, or in chemical transfer applications, we offer our Series TVCLT Chlorine Transfer Hose. This hose is constructed with a helical convoluted bore PTFE liner, PVDF braids, and a special CPE cover. Fittings are installed at the factory.

Unisource also provides smooth-bore PTFE hose, check out our PTFE Smooth-Bore, High-Pressure Hose section for more information. We also offer a section on FEP Lined Rubber Hose.

Also, check out our website sections on Chemical Hose, products for Cryogenic and Compressed Gas, and Sanitary Hose for more applications.

Return to PTFE & FEP Hose page.

Series TSV Standard Convoluted PTFE Hose – Tape Wrapped

Hose:

Non-conductive virgin convoluted PTFE with PTFE / fiberglass tape wrap. (Style TSV-B is conductive lined, virgin PTFE)

Reinforcing:

300 series stainless steel wire overbraid

Temperature Range:

-65°F to +400°F

Pressure Range:

500 PSIG to 1400 PSIG (Depending on size)

Sizes:

True-bore: -6 to -32 (3/8” to 2”)

Packaging:

Sold as custom assemblies only

Applications:

Choose Unisource Style TSV Convoluted PTFE Hose when you require the chemical inert, long-life properties of PTFE, but product flexibility is a prime consideration.

Style TSV combines an inner core of convoluted PTFE, externally reinforced with PTFE-impregnated fiberglass and Series 300 stainless steel wire braid. Style TSV-B hose is formulated using PTFE with carbon black additive near the tube surface. This material provides a continuous conductive path to the metal end fittings, dissipating static electricity build-up. A high pressure rated assembly is complete by attaching special swage type fittings made in a variety of styles.

This tape-wrapped, convoluted style hose is used in a variety of applications in chemical plants,food processing and pharmaceutical plants, pulp and paper mills, oil refineries, and particular O.E.M.systems. Select either conductive or non-conductive depending on the application. Some applications require a conductive inner line to dissipate static electrical charges. High resistivity fluids or gases at high velocity cause positive electrical charges to build on the inside of the PTFE liner. If not dissipated to the end of the hose, the charge will build until it arcs through the tube wall to the braid, causing catastrophic hose failure. Specify Style TSV-B with a thin conductive liner on the I.D. for static dissipation when this situation is present. Specify Style TSV-HV for full vacuum applications.

Style TSV hose has a temperature range of -65°F. to 400°F. continuous service. Working pressure ratings range from 500 PSIG (2”) to 1000 PSIG (3/8”), depending on size, all with a 4:1 safety factor.

| Part # (TSV) | Part # (TSV-B) | Nominal Hose Size (In) | Avg. O.D. (In) | Oper Pressure (PSIG) | Burst Pressure (PSIG) | Bend Radius (In) | Max Continuous Lengths (Feet) |

|---|---|---|---|---|---|---|---|

| 6TSV | 6TSV-B | 3/8 | 0.59 | 1,000 | 4,000 | 1.00 | 75 |

| 8TSV | 8TSV-B | 1/2 | 0.76 | 1,250 | 5,000 | 1.50 | 75 |

| 10TSV | 10TSV-B | 5/8 | 0.91 | 1,400 | 5,600 | 2.00 | 50 |

| 12TSV | 12TSV-B | 3/4 | 1.07 | 1,100 | 4,400 | 2.50 | 50 |

| 16TSV | 16TSV-B | 1 | 1.34 | 1,000 | 4,000 | 3.00 | 50 |

| 20TSV | 20TSV-B | 1-1/4 | 1.57 | 1,000 | 4,000 | 3.50 | 50 |

| 24TSV | 24TSV-B | 1-1/2 | 1.81 | 750 | 3,000 | 4.50 | 50 |

| 32TSV | 32TSV-B | 2 | 2.32 | 500 | 2,000 | 5.25 | 50 |

Series TSVO Open Pitch Convoluted PTFE Hose

Tube:

Virgin PTFE, wide convolutions. White or static-conducting black)

Reinforcement:

Stainless steel braid. Poly braid or PVDF available upon request

Applications:

Style TSVO is an open pitch convoluted PTFE hose found in a wide variety of sanitary, high-temperature, and high-tech applications. This hose has an internal profile that supports high flow rates and the helical design aids in self draining. The fluoropolymer core is inert and offers long flexural life, low permeability and the lowest coefficient of friction of any solid material. The core is seamless, heavy-wall extruded white or black-conductive PTFE tubing and is contained by a stainless steel braid. Polypropylene braid cover and polypropylene flanges are also available. The tube is formed from a solid homogeneous PTFE extrusion. The internal convolutions are shaped to ensure pure flow, and is 100% cleanable. The PTFE is thicker than most conventional hose and provides superior vacuum ratings and “hoop” strength. Series TSVO is easy to flex yet won’t flatten when bent, and is extremely crush resistant. A primary advantage of a thick tube design is its ability to be extended through the fittings and flared over to form a sealing face, eliminating any joint between fitting and hose. Flow is uninterrupted and the assembly is completely free of areas where corrosion or bacteria can build up. Meets FDA and USDA requirements.

| Nominal I.D (Inches) | Stainless Braid W.P. | Polypro Braid W.P. | Unbraided W.P. | Minimum Bend Radius (In.) | Vacuum Raiting (In. Hg.) | Weight Per Food (Lbs) |

|---|---|---|---|---|---|---|

| 1/2 | 400 PSIG | 400 PSIG | 40 PSIG | 1.75 | 29.9 | 0.20 |

| 3/4 | 400 PSIG | 400 PSIG | 30 PSIG | 2.25 | 29.9 | 0.35 |

| 1 | 400 PSIG | 400 PSIG | 30 PSIG | 2.50 | 29.9 | 0.50 |

| 1 1/4 | 325 PSIG | 275 PSIG | 20 PSIG | 3.00 | 29.9 | 0.70 |

| 1 1/2 | 325 PSIG | 250 PSIG | 20 PSIG | 3.25 | 29.9 | 0.80 |

| 2 | 325 PSIG | 225 PSIG | 15 PSIG | 5.25 | 29.9 | 0.95 |

| 2 1/2 | 250 PSIG | 200 PSIG | 15 PSIG | 8.50 | 29.9 | 1.50 |

| 3 | 175 PSIG | 175 PSIG | 15 PSIG | 9.50 | 24.0 | 1.79 |

| 4 | 150 PSIG | 150 PSIG | 15 PSIG | 11.95 | 20.0 | 2.25 |

| 6 | 75 PSIG | 50 PSIG | 5 PSIG | 15.50 | 15.0 | 3.50 |

Series TVCLT Convoluted Chlorine / Bromine Hose

Inner Hose:

Virgin convoluted 0.045 wall PTFE with integral fiberglass covering

Reinforcing:

Two layers of KYNAR braid

Covering:

1” Assemblies have a blue CPE pin-pricked jacket (vent drilled)

Temperature Range:

-40°F to +120°F

Branding:

1” Assemblies have a molded label every three feet stating manufacturer and design specs

Meets Industry Standard:

Chlorine Institute Deg. No. 135, Issue 2

Packaging:

Sold as custom assemblies only

Applications:

Unisource Style TVCLT convoluted PTFE hose is the ultimate in the highly critical transfer of Chlorine / Bromine. The special construction of this hose provides assemblies that are more flexible and resilient than metal hose. The convoluted PTFE tube is virtually stress-free in continuous flexing installations.

Style TVCLT is constructed using a convoluted 0.045” nominal thickness heavy-wall PTFE inner core, with an integral fiberglass covering. The inner core is then reinforced with two (2) layers of KYNAR braided directly onto the inner core. Our 1” assemblies are intended for rail car loading and unloading service. These 1” assemblies are covered with a blue 3/16” thick CPE “pin-pricked” jacket with a molded label every three feet, stating manufacturer and design specifications in accordance with industry standards. The “pin-pricked” cover is actually “vent-drilled” (1/8” dia) every 18”. The 1/2” assemblies are intended for use as pigtail / whips in filling plants, and do not utilize a CPE jacket, but are double braided with blue KYNAR.

All fittings and crimp collars are precision machined from Monel.

Assemblies are 100% inspected and pressure tested. Meets or exceeds the Chlorine Institute guidelines, Drawing No. 135, Issue 2.

| Size | Operating Pressure (PSIG) | Burst Pressure (PSIG) | Bend Radius (In) |

|---|---|---|---|

| 1/2 Assy | 500 | 2,000 | 1.5 |

| 1” Assy | 375 | 1.875 | 6.0 |