Count on Unisource to build metal expansion joints custom to your application. Whether your media is steam, engine exhaust, hot air, gases, or something else, we can design metal expansion joints based on expected pipe movements, temperature extremes, working pressures, velocity, anchor loads, and other conditions. Stainless steel bellows or special alloy material can be a single set of bellows or dual. Bellows interior can be lined for smooth flow. Spring rates can be modified in construction to reduce anchor loads. End configurations can be flanged or weld ends. Covers are available to protect the outer bellows from the elements. Tie rods or limit rods can be added to control bellow extension. As far as types of metal expansion joints, choose from simple bellows, controlled-flexing, universal style, pressure balanced, hinged, gimbaled, externally pressurized, rectangular, or flexible V-Loops constructed using flexible metal hose (see our Products for HVAC web section for additional information), In addition, we offer a complete assortment of pipe alignment guides and can assist with determining their required number and placement. All of our metal expansion joints are built using standards from EJMA (the Expansion Joint Manufacturers Association).

Series FFB Stainless Steel Bellows

Expansion Joints

Series FFB Free-Flexing Metal Expansion Joints are manufactured using multi-corrugation metal bellows, and flanged or weld type end connections. Accessories such as tie rods, limit rods, flow liners, and covers can be added, depending on the application. Free-flexing expansion joints are used to control axial pipe movements that typically arise due to thermal expansion. Limited lateral offset, angular rotation, and vibration isolation can also be accommodated. Mid-corrugation bellows are an economical choice when average movements are experienced. High-corr bellows should be used to absorb greater movements. Where expected motions are greater than what a single bellows can accommodate, dual bellows with a center anchor base can be used. Bellows pressure carriers include low pressure exhaust bellows, 50 psi, 150 psi, and 300 psi. Single ply bellows are standard. Multi-ply bellows are well suited for those applications requiring low spring rate or where cyclical vibration may be a problem. Standard materials include T304, 321, and 316 stainless steel, as well as Inconel, Monel, and other alloys. Meets MIL-E-17813F Type 1, Class 1 and Class 2. Series FFB bellows expansion joints are designed and constructed per application to meet specific design requirements regarding combinations of pressure, temperature, motions, and cycle life. All Series FFB bellows are manufactured in accordance with the Expansion Joint Manufacturers Association (EJMA).

- Single or dual bellows

- Variety of pressure ratings

- Can be constructed using type 316 stainless steel or other special alloys

- Available in standard corr height or high-corr

- Multi-ply bellows for vibration handling, low spring-rates, & longer life

- Internal liners for high velocity media

- Limit rods or tie rods can be added when needed

Pressure Range |

Sizes |

Bellow Material |

End Connections |

Standards |

| Up to 300 PSIG | 2″ to 144″ diameter | 304, 321, or 316 stainless steel, Inconel, Monel, or other alloys | Fixed flange, floating flange, or beveled weld end style | EJMA, MIL-E-17813F Type 1 Class 1 & 2. ASME welding standards. |

Series CF Controlled-Flexing Expansion Joints

Series CF Controlled Flexing Metal Expansion Joints combine high-corrugation free flexing bellows with mated neck rings, and equalizing or control rings. This heavy-duty construction allows their use with higher pressures and larger axial movements than a standard high-corr unit would be able to accommodate. Each of the equalizing rings that fit into the corrugations are extended in a “T” shape over the bellows. The tops of these rings will begin to make contact when the bellows are compressed, spreading the movement equally over each convolution. Bellows squirm and buckling is controlled. Controlled flexing expansion joints are ideal for steam piping to compensate for thermal growth. Selections include either 150# or 300# bellows, and in single or dual configuration. End fittings can be plate flange, forged flange, or weld ends. Controlled-flexing joints are rated for full-vacuum, and temperatures from -20 to 800°F. Meets MIL-E-17813F Type II Class 1 or 2.

Pressure Range |

Sizes |

Bellow Material |

End Connections |

Standards |

| Up to 300 PSIG | 2″ to 144″ diameter | 304, 321, or 316 stainless steel, Inconel, Monel, or other alloys | Fixed flange, floating flange, or beveled weld end style | EJMA, MIL-E-17813F Type 1 Class 1 & 2. ASME welding standards. |

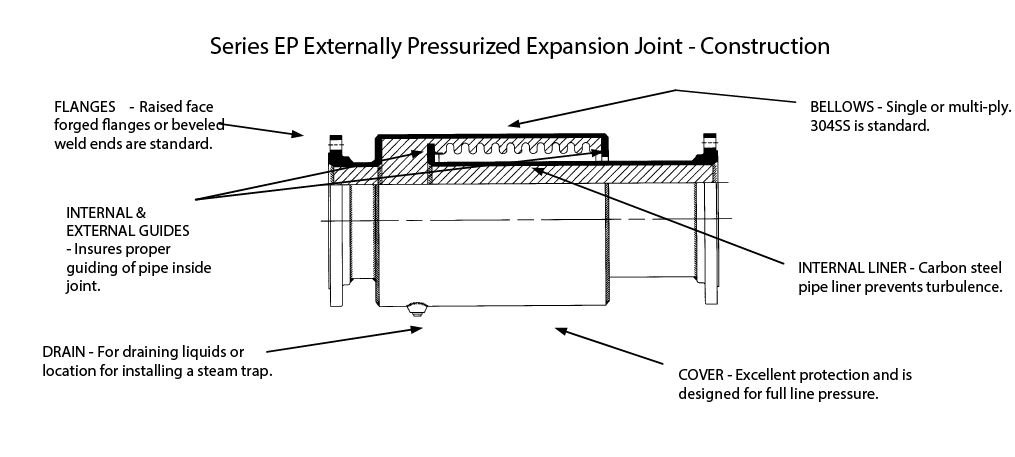

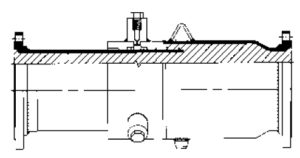

Series EP Externally Pressurized Expansion Joints

– Single & Dual Units

Series EP Externally Pressurized Expansion Joints are used in straight runs of pipe to accommodate large amounts of thermal expansion. Typical applications would include steam systems, where extreme temperature differentials would cause thermal growth of the piping system. Series EP expansion joints are a packless, maintenance-free joint that incorporates an all stainless steel flexible bellows, a steel enclosure, with external and internal guide ring/sleeve to maintain alignment of the inner pipe. The sleeve isolates the bellows from media, eliminating flow turbulence. External pressure is applied to the bellows via a gap between the internal flange and housing. Movement limitation is accomplished by means of an internal flange, and also guides the bellows along the longitudinal centerline. The external pressure keeps the bellows stable.

Externally pressurized expansion joints have significant advantages over pipe loops because they are able to absorb very large axial movements and take up far less space than pipe loops. Typically these applications are indoors, in utility tunnels, or buried where extra space is not available. Series EP joints also are frequently specified instead of slip joints that are also engineered for large movements because of several factors.

Slip joints are a packed product that required periodic inspection and maintenance. Access vaults are always required for packed joints. Series EP externally pressurized joints are of a packless, all-welded construction that does not require inspection and can be installed in remote locations or even directly buried. Unisource Series EP externally pressurized expansion joints are a long-life quality piping product that carries a Five-Year Limited Leak-Free/Maintenance-Free Warranty. Contact Unisource for details.

Select either 150 PSIG or 300 PSIG bellows construction. Single bellows styles are available for 4″, 6″, or 8″ of axial travel. Dual bellows units with center anchor base are rated for 8”, 12”, or 16” of axial travel. Flanges or weld end are additional options. Meets MIL-E-17813F Type II Class 4. Standard bellows are constructed of single ply or multi-ply Type 304 stainless steel and are suitable for most chloride free applications such as steam, condensate, oil, and chilled water. Where chlorides may be present, Inconel 600 bellows should be specified. Special bellows material would include 316SS, 321SS, Inc 600, and Inc 625. Other bellows alloys are available upon request. Pipe and end connections are plain steel.

For submittal sheets on 300 PSI units or dual units, contact Unisource.

Pressure Range |

Anchor Base |

Bellow Material |

Drain Port |

End Connections |

Lifting Lugs |

Pipe/Shell |

| 150 PSIG & 300 PSIG Styles | None. Can be ordered | Single ply or multiply 304SS | Carbon steel with tapered plug | Fixed 150# or 300# flanges ANSI B 16.5, or beveled weld ends | Used on all units | Carbon steel Sch Standard |

Series EP Externally Pressurized Expansion Joints are used in straight runs of pipe to accommodate large amounts of thermal expansion. Single bellows styles are available for 4″, 6″, or 8″ of axial travel. Series EPD dual expansion joints utilize two sets of bellows with a center anchor base, effectively doubling the axial motion capability of a single expansion joint. Dual units are rated for either 8”, 12”, or 16” of axial travel. Anchor base is stanadard.

Select either 150 PSIG or 300 PSIG bellows construction. Flanges or weld end are additional options.

Pressure Range |

Sizes |

Anchor Base |

Axial Travel |

Bellow Material |

Drain Port |

End Connections |

Lifting Lugs |

Pipe/Shell |

| 150 PSIG or 300 PSIG Styles | 1-1/2″ through 14″ | Carbon steel intermediate anchor base (standard with dual units) | From 4” thru 16″ | Single ply or multiply 304SS | Carbon steel with tapered plug | Flanges – 150# or 300# ANSI B 16.5 RFSO C/S, ASTM 105 Forged. Weld Ends – Sch 40 C/S beveled | Carbon steel. Used on all units | Carbon steel Sch Standard |

Ultralon PTFE Lined Metal Bellows

The unique Unisource “Ultralon” metal expansion joints combines the properties of metal and fluoroplastics into the most advanced, versatile expansion joint on the market today. Ultralon was designed to meet the process piping needs of the high-technology, chemical/petrochemical, power generation, pulp and paper, and other demanding needs. The Ultralon expansion joint is versatile and will:

- Absorb pipe movements and stress

- Isolate mechanical vibration

- Reduce system noise

- Protect against surge forces

Ultralon is a problem solving product in many high temperature applications. Unlike ordinary solid PTFE or elastomeric joints, should up-set conditions exceeding 500 °F occur, Ultralon will maintain its pressure carrying capacity up to 1200°F—long enough for system shut-down and replacement.The construction of the Ultralon expansion joint utilizes a stainless steel, Inconel, Monel, or Hastelloy bellows in combination with a PTFE lining formed into the bellows during manufacture.

Ultralon expansion joints can offer working temperatures from -300°F to +400°F, and a choice of bellows rated for working pressures of 50, 150, or 300 psi. Gimbal, hinged, dual externally pressurized, and pressure balanced styles are construction options. Flanges are available in carbon steel, stainless steel, or Teflon coated. Ultralon expansion joints can be manufactured in custom overall lengths and in custom movement capabilities. Consult Unisource for information on the special construction you need for your application.

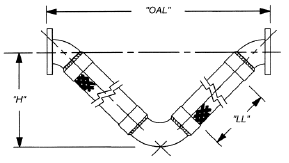

Unisource “V-Loop” Flexible Loops for Pipe Growth & Seismic

Specified by consulting engineers and building owners and installed by contractors throughout the world for many years, Unisource V-Loops solve the problems of pipe motion caused by thermal pipe growth and the unpredictable movements associated with seismic activity. Unisource V-Loops can perform the functions of large pipe loops or expansion joints, and in addition, can provide protection and flexibility in multiple planes during potentially catastrophic earthquakes.

Unlike large pipe loops, Unisource V-Loops take up a minimum of space, providing pipe motion accommodation solutions in limited space situations such as indoor piping. The small configuration of the V-Loops are also far less susceptible to the heat loss that must be dealt with in the case of large pipe loops.

Whereas metal bellows or rubber expansion joints will impose substantial anchor loads due to the effects of static pressure thrust, Unisource V-Loops will not introduce any thrust loads on the piping system. The unique construction of the braided V-shaped loop creates a flexible product that does not expand when pressurized. A welded-on braid acts as a restraining device, even at extended pressures, yet allows tremendous flexibility. Anchor loads in regard to the Unisource V-Loops are confined to the relatively small spring forces required to deflect the flexible legs within the loop. Unlike expansion joints, a minimum of pipe guiding is required

Unisource V-Loops are extremely easy to design in nested configurations. Due to the inherent V-design, standard V-Loops can simply be nested within each other with relatively tight centering. A substantial amount of space can be saved, and since no additional pipe extensions need to be installed in the Unisource V-Loops, standard models can be used, saving cost and reducing delivery time.

The standard position for the Unisource V-Loop is in a horizontal pipe run, with the elbow pointing straight down. Positioning is versatile, however, and the loops can be installed in many other positions such as laying the loop horizontal, positioning the elbow straight up, or positioning for vertical pipe runs. In installations other than the standard position, Unisource can provide a support eyelet to allow a cable or rod to support the weight of the loop and its contents.

Unisource V-Loops can be used for a variety of fluids and gases. Loops can be constructed using stainless steel hose and braid with carbon steel end fittings and elbows, or with bronze hose and braid with copper end fittings and elbows. End fitting options include flanges, male threads, beveled weld ends, grooved ends, and copper sweat. Use Unisource V-Loops for applications such as heating and cooling water in HVAC systems; moderate velocity steam; natural gas; medical gases; fire sprinkler piping; and selected process applications. Drain ports can be added where required

For higher pressure applications, Unisource V-Loops can be constructed using double braided hose legs. Consult Unisource for specific pressure ratings.

Standard Unisource V-Loops are offered for either 2” or 4” of motion from center-line in axial and offset planes. Loops for even greater motions can be constructed upon request.

All Unisource V-Loops are shipped complete with installation instructions wire tagged to each product. Unisource offers loops for applications under the auspices of the CSA/AGA, NFPA, and U.L.

Why V-Loops Instead of Bellows?

Unisource V-Loops are an ideal option for compensating for thermal pipe growth. Often, thermal pipe growth must be absorbed in piping systems where the substantial anchoring systems that bellows expansion joints would require are not present. Since these “V” shaped flexible hose loops do not impose pressure thrust forces on the anchoring system, anchor loads are very low. The only forces involved are the spring forces required to flex the loops. Unisource V-Loops are an in-line connector and consist of a 90-degree pipe elbow with a flexible stainless steel or bronze hose leg connecting to each end of the elbow. 45-degee pipe elbows are located at the ends of the flex leg and end fittings are welded to the 45-degree elbows. End options are flanges, pipe threads, beveled weld ends, grooved ends, and copper sweat ends. Standard V-Loops are rated for either 2” or 4” of motion, but can be build to absorb greater movements. Since Unisource V-Loops do not impose thrust forces on the pipe system, a minimum of guiding is required. For steam applications, a drain port can be added at the center elbow. Loops can be configured with the 90-degree elbow hanging straight down or with support at the 90-degee elbow, can be positioned in an inverted position, horizontal, or in a vertical riser application.

See the HVAC section under Special Market Focus more more information and submittal on Unisource V-Loops.

Elbows |

Pressure Range |

Sizes |

Braid |

Allowable Motions |

Drain Port |

End Connections |

| Carbon steel, stainless steel, or copper | 160 PSIG to 1335 PSIG (Depending on size). Double braided higher pressure loops also available | 1/2″ through 12″ | Choose either 300 series stainless steel or bronze | 2” or 4″ are standard. More motion can be accommodated upon request | Carbon steel or bronze with tapered plug | Flanged, threaded, beveled weld end, grooved, copper sweat |

Special Design Expansion Joints

Unisource offers many types of specially designed metallic expansion joints. Depending on whether your particular piping problem involves accommodating large amounts of offset motion, single plane or multi-plane angular movements, or severely reducing anchor loads, we can design and built a product for your application.

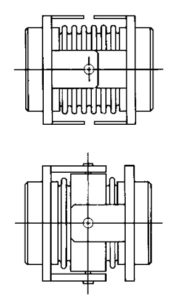

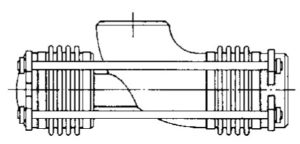

Universal Expansion Joints

The universal design consists of a dual bellows separated by a center pipe spool (see picture above right). Optional tie rods can be attached to limit growth of the joint. Universal expansion joints are typically used to accommodate large amounts of lateral motion. When they are used in conjunction with 90 degree piping direction changes, they can be used in pipe runs where extensive anchoring and guiding cannot be provided. Force required to offset is low provided adequate length is available. As the length between the bellows increases, the spring rate decreases.

Hinged & Gimbaled

Expansion Joints

In situations where only angular movement is to be allowed, hinged and gimbaled expansion joints are the solution. Hinged joints are designed to take up angular motion in a single plane. Slotted hinge expansion joints permit axial movement through use of a slot, and require main anchors. Gimbal bellows will allow angular motion in all planes. Hinged and gimbaled joints are commonly used in combination to absorb various movements.

Pressure Balanced Expansion Joints

An elbow style expansion joint designed for applications involving 90 degree change of direction and situations where main anchors cannot be placed in the system. The elbow is permitted to float free of bellow thrust forces. Either single or dual bellow pressure balanced are available. In-line pressure balanced expansion joints are constructed for axial applications of straight runs of pipe that cannot provide main anchors to react the pressure thrust of the expansion joint.

Slip-Pak Expansion Joints

Slip-Pak expansion joints are an excellent choice when a heavy-duty, long-life product is needed to take up large amounts of axial motion. Ideal for new construction when piping well aligned. Movements can be absorbed at high pressures and temperature. These joints are internally and externally guided. Long product life is assured by re-packing while in service. Meets MIL-E-17814E. Available in single or dual configurations.

Rectangular Expansion Joints

Rectangular metallic bellows expansion joints are fabricated to absorb vibration and thermal movements in duct systems. High profile, low spring-rate corrugations will allow for large amounts of movement in short face-to-face designs. Flanges can be either internal or external. A variety of alloys can be used to assure trouble-free operation in high temperature conditions. Axial, lateral, and angular movement can all be accommodated. Similar low-pressure bellows are also manufactured for circular duct systems.

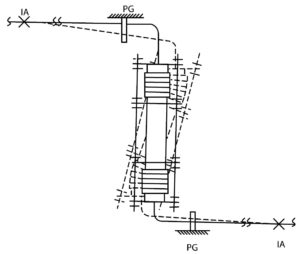

Pipe Alignment Guides

Series PG Pipe Alignment Guides

Series PG Pipe Alignment Guides should always be used in conjunction with metal expansion joints. Pipe alignment guides help to control the motion of pipe and expansion joints, insuring that the joint is subject only to the deflection for which it was designed. Unguided piping, under pressure will tend to buckle, sometimes severely. This buckling would deter the expansion joints from working properly. Guides permit unobstructed axial movement of the pipe while restricting lateral, angular, or buckling movements.

Standard spider guides are manufactured to accommodate specific amounts of movement and insulation. A pipe guide assembly consists of an anchored housing and a sliding spider that is attached to the pipe. The spider moves through the housing as the pipe expands and contracts. Guides are carbon steel painted for rust protection. Additional items in this series include pre-insulated guides, pipe slides and bases, anchor clamps, baseboard fin-tube guides, baseboard anchors, and hinged series.

FEATURES

- Available in sizes 1/2” to 24″

- Constructed of carbon steel and painted for rust protection

- For piping styles: steel, stainless steel, copper (requires dielectric spacer)

- Will accommodate from 1” to 4” of insulation

- Spider and housing can be built to take from 3” to 12” of axial motion

Basic Expansion Joint Information

The information on the brochure below is important basic guidelines to consider when placing metal expansion joints into a piping system. When bellows expansion joints are being considered to absorb pipe movements, concepts such as pressure thrust force, spring forces, pipe guiding, and anchoring need to be thoroughly analyzed. In addition, pipe movements due to thermal changes or other situations must be accurately calculated. The attached brochure will assist in determining the proper metal expansion joints and piping components.