PTFE smooth-bore, high pressure hose are the ideal choice for many chemical, gas, and high-purity applications. The broad Unisource line-up of PTFE hoses are ideal for each of these situations. Known as 3000 PSI, 5000 PSI and 6000 PSI hose specs (depending on size), these hoses are available in different reinforcing styles–braid, bunch braid, and spiral/braid combinations. Reinforcing is made of Series 300 stainless steel. PTFE is a fluoropolymer that provides the industry’s best all-around chemical resistance. At the same time, it offers both a very high (up to +450 Deg. F.) and low temperature rating (-65 Deg. F.). In addition, PTFE hose is virtually non-aging. It withstands continuous flexing, vibration and impulse. PTFE hose will find its uses in many industries. Choose white PTFE or static-conducting black tube. Our 5000 PSI and 6000 PSI hoses are made with a post-sintered PTFE tube for low effusion of gases. Available in bulk lengths or complete assemblies with fittings. Various types of testing is also available.

For applications where you require the high-temperature, high-pressure characteristics of flexible metal hose, but also need a smooth-bore PTFE liner, our SF-TSC Series hose will do the trick. Very often used as short flex connectors between chemical tanks and permanent piping, SF-TSC hose assemblies are manufactured with PTFE flared over stainless steel stub ends and backing flanges are 304 or 316 stainless steel.

Refer to our PTFE Convoluted Bore Hose section for information on all types of convoluted PTFE hose. Also check out our section on FEP Lined Rubber Hose.

Check out our website section on products for Cryogenic and Compressed Gas, for more applications.

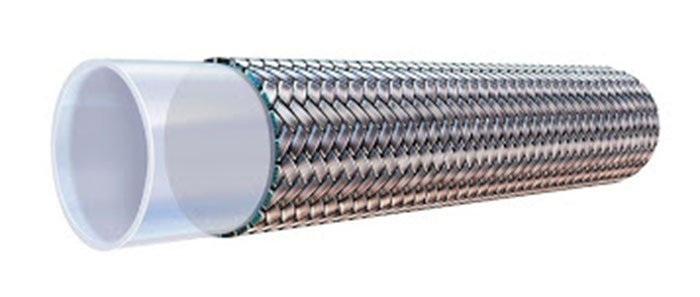

Series TSC Smooth-Bore PTFE Hose

Liner:

Virgin PTFE, wide convolutions. White or static-conducting black (TSC-B)

Reinforcing:

Stainless steel braid. Poly braid or PVDF available upon request

Temperature Range:

-65°F to +450°F

Pressure Range:

750 PSIG to 3000 PSIG (Depending on size)

Sizes:

3/16″ through 1-1/4″

Packaging:

Sold as custom assemblies only

Applications:

Style TSC combines a smooth-bore PTFE inner core with a 300 series stainless steel overbraid. A high pressure rated assembly is complete by attaching special swage type fittings made in a variety of styles. Smooth-bore, medium pressure PTFE hose is utilized in many applications, including pharmaceutical, high-pressure gas, food procesing, bio-tech, chemical transfer, and process water. It can be found installed in gas cylinder filling plants, factories, on trucks and buses, automobiles, and a myriad of OEM equipment. PTFE hose may be the ideal solution if the application requirement exceeds the chemical, heat, and other limitations of rubber, metal and plastic hose.

| Part # | Nominal Size (In) | Avg. I.D. (In.) | Avg. O.D. (In) | Maximum W.P. (PSI) | Burst Pressure (PSI) | Bend Radius (In.) |

|---|---|---|---|---|---|---|

| 3TSC | 3/16 | .125 | .250 | 3,000 | 12,000 | 2.0 |

| 4TSC | 1/4 | .187 | .312 | 3,000 | 12,000 | 2.0 |

| 5TSC | 5/16 | .250 | .375 | 3,000 | 12,000 | 3.0 |

| 6TSC | 3/8 | .312 | .445 | 2,500 | 10,000 | 4.0 |

| 7TSC | 7/16 | .375 | .503 | 2,250 | 9,000 | 4.5 |

| 8TSC | 1/2 | .405 | .549 | 2,000 | 8,000 | 5.2 |

| 10TSC | 5/8 | .500 | .648 | 1,500 | 6,000 | 6.5 |

| 12TSC | 3/4 | .625 | .778 | 1,200 | 4,800 | 7.7 |

| 14TSC | 7/8 | .750 | .885 | 1,100 | 4,400 | 8.2 |

| 16TSC | 1 | .875 | 1.030 | 1,000 | 4,000 | 9.0 |

| 18TSC | 1-1/8 | 1.000 | 1.135 | 900 | 3,600 | 10.0 |

| 20TSC | 1-1/4 | 1.125 | 1.290 | 750 | 3,000 | 16.0 |

Series TSHP Smooth-Bore High-Pressure Hose

Liner:

Medium wall, anti-static, smooth-bore PTFE – post sintered

Reinforcing:

Bunch braided high-tensile 304 stainless steel

Temperature Range:

-76°F to +500°F

Sizes:

1/4” thorough 1-1/2″

Pressure Range:

4,000 PSI to 5,000 PSI (depending on size)

Packaging:

Sold as custom assemblies only

Applications:

Series TSHP is a high pressure hose that combines a light weight construction with an anti-static PTFE liner. Ideal for hydraulic applications and due to a post-sintering, excellent for most gas applications. High-tensile bunch braid reinforced.

| Part # | Nominal Size (In) | Wall Thickness (In) | Braid O.D. (In) | Maximum W.P. (PSIG) | Burst (PSIG) | Bend Radius (In) |

|---|---|---|---|---|---|---|

| 4TSHP | 1/4 | 0.041 | 0.375 | 5,000 | 16,000 | 1.5 |

| 6TSHP | 3/8 | 0.041 | 0.473 | 5,000 | 16,000 | 2.5 |

| 8TSHP | 1/2 | 0.046 | 0.600 | 5,000 | 16,000 | 2.9 |

| 10TSHP | 5/8 | 0.051 | 0.710 | 5,000 | 16,000 | 3.3 |

| 12TSHP | 3/4 | 0.051 | 0.970 | 5,000 | 16,000 | 4.0 |

| 16TSHP | 1 | 0.051 | 1.250 | 5,000 | 16,000 | 5.0 |

| 20TSHP | 1-1/4 | 0.071 | 1.600 | 4,000 | 12,000 | 12.0 |

| 24TSHP | 1-1/2 | 0.071 | 1.92 | 4,000 | 12,000 | 14.0 |

Series TSHD Smooth-Bore Extreme Pressure Hose

Liner:

Post-sintered, static-conducting, smooth bore PTFE

Reinforcement:

Multiple layers of braided and spiraled 304 stainless steel

Temperature:

-76 Deg. F. to 500 Deg. F.

Sizes:

1/4” through 1″

Pressure Range:

4000 PSI to 6000 PSI (depending on size)

Packaging:

Sold as custom assemblies only

Applications:

Series TSHD is a heavy-weight, extreme-pressure hose with a smooth-bore, static-conducting PTFE liner. Appropriate for high-impulse, high-cycle applications. The post-sintered PTFE liner offers low effusion, making it ideal for many gas applications. Reinforced with multiple braids and spirals of 304 stainless steel.

| Part # | Size (In) | Wall Thickness (In) | Braid O.D. (In) | Max W.P. (PSIG) | Min. Burst (PSIG) | Bend Radius (In) |

|---|---|---|---|---|---|---|

| 4TSHD | 1/4 | 0.041 | 0.485 | 6,000 | 24,000 | 3.00 |

| 6TSHD | 3/8 | 0.041 | 0.594 | 6,000 | 24,000 | 5.00 |

| 8TSHD | 1/2 | 0.051 | 0.733 | 6,000 | 24,000 | 5.75 |

| 10TSHD | 5/8 | 0.051 | 0.910 | 4,000 | 12,000 | 6.25 |

| 12TSHD | 3/4 | 0.051 | 1.055 | 4,000 | 12,000 | 7.75 |

| 16TSHD | 1 | 0.051 | 1.325 | 4,000 | 12,000 | 9.63 |

Series SF-TSC Flexible Metal Hose with Liner

Liner:

Smooth-bore, white PTFE flared over metal stub ends

Metal Hose:

Annular corrugated Series 300 stainless steel (321 or 316 available)

Reinforcing:

304 stainless steel braid (316 S/S available) – single or double braid

Temperature Range:

-65 Deg. F. to 350 Deg. F.

Flange Types:

Carbon steel, 304 or 316 stainless – ANSI Class 150 or 300 lb. Flanges rotate.

Applications:

Unisource Series SF-TSC hose utilizes a very specialized construction to create a flexible connector suitable for the most severe applications. Series SF-TSC is constructed using close-pitch, annually corrugated metal hose. A smooth-bore white PTFE liner is inserted into the hose and locked into place. Ends of the PTFE liner are flared over the stainless steel stub retainers that are welded to each end of the hose. This creates a hose connectors with all wetted surfaces being PTFE. Floating flanges rotate behind the tube retainers.

Corrugated metal hose can be either T321 stainless steel or T316 stainless steel. Standard single braid is made of T304 stainless steel. Special T316 stainless steel braid material is available on special order. Floating flanges do not contact the stream flow, and can be constructed of carbon steel, T304 or T316 stainless steel.

Series SF-TSC hose is often used as a short connector between mechanical equipment or tanks and the solid piping system. They are often used to help reduce the effects of equipment induced noise, vibration, or shock, and offset movements caused by seismic activity or equipment settling. Series SF-TSC connectors provide high working pressures, superior corrosion resistance, and moderate flexibility–even at elevated temperatures.

| Size (In) | W.P. @ 70 Deg. F. (PSIG) | W.P. @ 350 Deg. F. (PSIG) | Bend Radius (In) | Vacuum Rating @ 70 Deg. F. (In. Hg.) | Approx Weight Per Foot (Lbs) |

|---|---|---|---|---|---|

| 1-1/2 | 400 | 330 | 15 | 29.9 | 3.90 |

| 2 | 300 | 250 | 21 | 29.9 | 5.00 |

| 3 | 200 | 165 | 28 | 29.9 | 5.25 |

| 4 | 150 | 120 | 46 | 20.0 | 5.50 |

| 6 | 150 | 120 | 65 | 20.0 | 13.0 |

| 8 | 125 | 100 | 89 | 20.0 | 20.0 |

| 10 | 100 | 80 | 112 | 20.0 | 26.0 |

| 12 | 90 | 70 | 116 | 20.0 | 35.0 |