We Provide Top US Companies the Highest-

Tell us what you need and our expert team of hose specialists will

send you a custom quote.

Our industrial rubber products are trusted by over 6,000 top U.S. companies

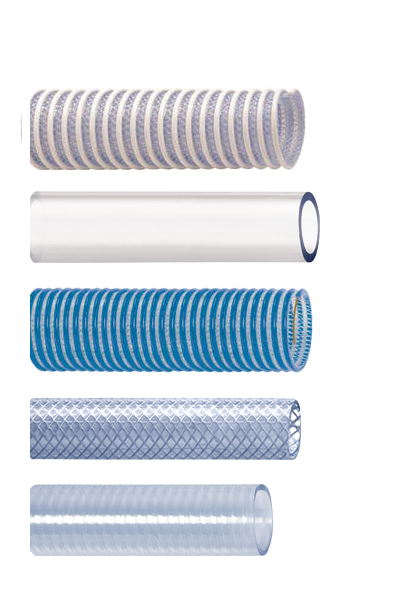

Series 1000 Clear Vinyl Tubing (FDA approved)

Construction:

Clear non-toxic PVC (FDA Approved)

Reinforcement:

None

Hardness:

78 Shore “A”

Temperature Range:

-25 Deg. F. to 150 Deg. F.

Note:

Made with NSF-51 approved materials

Origin:

USA

Applications:

This hose has good oil resistance, excellent resistance to acids, alkalis, and many solvents except esters, ketones and aromatic hydrocarbons. Phthalate Free.

| Part Number | I.D. (In) | O.D. (In) | Wall Thickness (In) | W.P. (@ 70 Deg. F) PSI | Weight (Lbs / Ft) | Std. Length | Stock (Yes) or Min. Order |

|---|---|---|---|---|---|---|---|

| 1000-0125 | 1/8 | 1/4 | 1/16 | 65 | .020 | 100' | Yes |

| 1000-0187 | 3/16 | 5/16 | 1/16 | 55 | .027 | 100' | Yes |

| 1000-025 | 1/4 | 3/8 | 1/16 | 55 | .034 | 100' | Yes |

| 1000-025H | 1/4 | 1/2 | 1/8 | 60 | .084 | 100' | Yes |

| 1000-038 | 3/8 | 1/2 | 1/16 | 45 | .056 | 100' | Yes |

| 1000-038H | 3/8 | 5/8 | 1/8 | 55 | .116 | 100' | Yes |

| 1000-050 | 1/2 | 5/8 | 1/16 | 30 | .074 | 100' | Yes |

| 1000-050H | 1/2 | 3/4 | 1/8 | 45 | .131 | 100' | Yes |

| 1000-063 | 5/8 | 7/8 | 1/8 | 40 | .158 | 100' | Yes |

| 1000-075 | 3/4 | 1 | 1/8 | 35 | .186 | 100' | Yes |

| 1000-087 | 7/8 | 1-1/8 | 1/8 | 30 | .211 | 100' | Yes |

| 1000-100 | 1 | 1-1/4 | 1/8 | 35 | .238 | 100' | Yes |

| 1000-125 | 1-1/4 | 1-3/4 | 1/4 | 40 | .672 | 50' | Yes |

| 1000-150 | 1-1/2 | 2 | 1/4 | 35 | .850 | 50' | Yes |

| 1000-200 | 2 | 2-1/2 | 1/4 | 30 | .964 | 50' | Yes |

Note:

Working pressure decreases as temperature increases. Pressure ratings can only be obtained with proper coupling procedures.

Series 1100 Clear Braided Tubing (FDA Approved)

Construction:

Clear non-toxic PVC (FDA Approved)

Reinforcement:

Multiple textile braids

Temperature Range:

-25 Deg. F. to 150 Deg. F.

Branding:

Ink – black letters

Note:

Made with NSF-51 approved materials

Origin:

USA

Applications:

Clear PVC hose is excellent for conveying liquids, air, and powdered foods. The hose is transparent, allowing for easy inspection during service. Formulated to meet applicable FDA, USDA, 3A, and NSF 51. Ideally suited for marine, recreational, agricultural and other industries. Phthalate Free.

| Part Number | I.D. (In) | O.D. (In) | W.P. @ 70 Deg. F. (PSI) | Weight (Lbs / Ft) | Std. Length | Stock (Yes) or Min. Order |

|---|---|---|---|---|---|---|

| 1100-025 | 1/4 | .468 | 250 | .05 | 100’/300' | Yes |

| 1100-038 | 3/8 | .595 | 225 | .10 | 100’/300' | Yes |

| 1100-050 | 1/2 | .750 | 200 | .13 | 100’/300' | Yes |

| 1100-063 | 5/8 | .875 | 200 | .15 | 100’/300' | Yes |

| 1100-075 | 3/4 | 1.030 | 150 | .19 | 100’/300' | Yes |

| 1100-100 | 1 | 1.300 | 125 | .28 | 100' | Yes |

| 1100-125 | 1-1/4 | 1.625 | 100 | .60 | 50’/100' | Yes |

| 1100-150 | 1-1/2 | 1.938 | 100 | .74 | 50’/100' | Yes |

| 1100-200 | 2 | 2.490 | 75 | 1.01 | 50’/100' | Yes |

Note:

Working pressure decreases as temperature increases. Pressure ratings can only be obtained with proper coupling procedures.

Series 1700 PVC Food Suction & Discharge Hose (FDA)

Construction:

Clear non-toxic PVC w/ rigid PVC helix

Color:

Clear w/ clear helix

Temperature Range:

-10 Deg. F to 140 Deg. F.

Vacuum Rating (In Hg):

29.8

Note:

Made with NSF-51 approved materials

Applications:

A flexible heavy-duty food-grade suction hose for the milk handling and food processing industries. In compliance with the criteria of 3-A Standard No. 20-00 and FDA. Acceptable to USDA for use in federally inspected meat and poultry plants.

| Part Number | I.D (In) | O.D. (In) | Bend Radius @ 70°F (In) | W.P. @ 70°F (PSI) | Weight (Lbs / Ft) | Std. Length | Stock (Yes) or Min. Order |

|---|---|---|---|---|---|---|---|

| 1700-100 | 1 | 1.24 | 1.9 | 85 | .26 | 100’ | Yes |

| 1700-125 | 1-1/4 | 1.54 | 2.7 | 80 | .37 | 100’ | Yes |

| 1700-150 | 1-1/2 | 1.82 | 2.0 | 70 | .44 | 100’ | Yes |

| 1700-200 | 2 | 2.39 | 2.5 | 70 | .74 | 100’ | Yes |

| 1700-250 | 2-1/2 | 2.93 | 4.7 | 70 | 1.01 | 100’ | Yes |

| 1700-300 | 3 | 3.43 | 6.1 | 60 | 1.21 | 100’ | Yes |

| 1700-400 | 4 | 4.53 | 9.1 | 50 | 2.01 | 100’ | Yes |

NOTE:

If the ambient or application temperatures vary from the 70 Deg. F. baseline, stated specifications and ratings for the hose will change.

Series 1780 Reinforced PVC Food Suction/Discharge Hose (FDA)

Construction:

Clear non-toxic PVC w/ Polyester Braid / Rigid PVC Helix

Color:

Clear w/white helix

Temperature Range:

-13 Deg. F. to 140 Deg. F.

Vacuum Rating (In Hg):

29

Note:

Made with NSF-51 approved materials

Applications:

Reinforced, flexible heavy duty PVC food grade suction hose designed for handling various food products. Braided reinforcement will accommodate higher working pressures while maintaining excellent flexibility and light weight. Typical applications include processing wine, beer, paste food, dairy and liquid foods. In compliance with criteria of FDA, USDA, and 3-A Sanitary standards requirements.

| Part Number | I.D. (In) | O.D. (In) | Bend Radius @ 70°F (In) | W.P. @ 70°F (PSI) | Weight (Lbs / Ft) | Std. Length | Stock (Yes) or Min. Order |

|---|---|---|---|---|---|---|---|

| 1780-150 | 1-1/2 | 2.03 | 2.5 | 110 | .56 | 100’ | Yes |

| 1780-200 | 2 | 2.60 | 4.0 | 100 | .75 | 100’ | Yes |

| 1780-300 | 3 | 3.70 | 6.3 | 100 | 1.20 | 100’ | Yes |

| 1780-400 | 4 | 4.78 | 7.1 | 75 | 1.74 | 100’ | Yes |

NOTE:

If the ambient or application temperatures vary from the 70 Deg. F. baseline, stated specifications and ratings for the hose will change.

Banding Coils (1 piece/2 ends)

| Part Number | Size (In) | Color |

|---|---|---|

| BC-150 | 1-1/2 | White |

| BC-200 | 2 | White |

| BC-300 | 3 | White |

| BC-400 | 4 | White |

Series 1880 Reinforced Polyurethane Food Grade Material Handling Hose

Construction:

Clear Polyurethane w/Polyester Braid & Rigid Blue PVC Helix (Static Wire Included)

Temperature Range:

-40 Deg. F to 150 Deg. F

Color:

Clear with blue helix

Applications:

This hose is specially designed for the handling of abrasive material in food grade suction and discharge applications. All compound materials comply with FDA requirements.

| Part Number | I.D. (In) | O.D. (In) | Bend Radius (In) | W.P. @ 70° F (PSI) | Vacuum Rating (In Hg) | Weight (Lbs / Ft) | Std. Length | Stock (Yes) or Min. Order |

|---|---|---|---|---|---|---|---|---|

| 1880-200 | 2 | 2.67 | 9.0 | 75.0 | 28.0 | .77 | 100' | 400' |

| 1880-300 | 3 | 3.78 | 10.0 | 70.0 | 29.8 | 1.18 | 100’ | Yes |

| 1880-400 | 4 | 4.85 | 12.0 | 65.0 | 29.8 | 1.58 | 100’ | Yes |

| 1880-500 | 5 | 5.80 | 14.0 | 45.0 | 28.0 | 2.47 | 20’/100’ | Yes |

| 1880-600 | 6 | 6.93 | 16.0 | 40.0 | 28.0 | 2.86 | 20’/100’ | Yes |

NOTE:

If the ambient or application temperatures vary from the 70 Deg. F. baseline, stated specifications and ratings for the hose will change.

Series 2450 FEP Lined Rubber Hose

Tube:

FEP (backed with modified XLPE)

Cover:

Blue EPDM

Reinforcement:

Multiple textile plies w/ dual wire helix

Temperature Range:

-40 Deg. F. to 300 Deg. F.

Vacuum Rating @ 70 Deg. F. (In Hg):

30

Design Factor:

4:1

Branding:

White Mylar/Black letters

Origin:

USA

Application:

Recommended for the transfer of products that require a hose tube with the highest level of chemical resistance. The smooth-bore design is ideal for the unrestricted transfer of fluids and promotes draining and cleaning. The hose is reinforced with multiple plies of polyester yarn with dual wire helix. This reinforcing combination provides full vacuum capabilities, kink resistance, and high working pressure ratings. Other cover colors are available (red, black, gray, yellow, green and white). Meets or exceeds the requirements of FDA & USDA under 21 CFR 177, 1550, 3-A sanitary standards 10-15.

Ask about custom assemblies of FEP lined rubber hose, higher working pressures, PTFE linings, etc.

| Part Number | I.D. (In) | O.D. (In) | Bend Radius (In) | W.P. @ 70° F (PSIG) | Weight (Lbs / Ft) | Std. Length | Stock (Yes) or Min. Order |

|---|---|---|---|---|---|---|---|

| 2450-075 | 3/4 | 1.29 | 4.0 | 200 | .52 | 100’ | 400’ |

| 2450-100 | 1 | 1.56 | 5.0 | 200 | .63 | 100’ | 400’ |

| 2450-150 | 1-1/2 | 2.05 | 8.0 | 200 | .93 | 100’ | 400’ |

| 2450-200 | 2 | 2.55 | 9.0 | 200 | 1.14 | 100’ | 400’ |

| 2450-300 | 3 | 3.59 | 18.0 | 150 | 1.77 | 100’ | 400’ |

Series 2700 Multi-Purpose Food Suction & Discharge Hose

Tube:

White Nitrile (FDA, 3-A, USDA compliant)

Cover:

Gray Nitrile / PVC Cover

Reinforcement:

Multiple textile plies w/dual wire helix

Temperature Range:

-25 Deg. F. to 230 Deg. F.

Branding:

Emboss

Application:

Series 2700 is a suction and discharge hose designed to handle oily and non-oily food products, liquids, sanitary products, and potable water in a variety of transfer applications.

| Part Number | I.D. (In) | O.D. (In) | Bend Radius (In) | W.P (PSIG) | Weight (Lbs / Ft) | Std. Length | Stock (Yes) or Min. Order |

|---|---|---|---|---|---|---|---|

| 2700-100 | 1 | 1.46 | 3.0 | 150 | .58 | 100’/200’ | 400’ |

| 2700-150 | 1-1/2 | 1.97 | 4.0 | 150 | .85 | 100’/200’ | 400’ |

| 2700-200 | 2 | 2.48 | 4.5 | 150 | 1.22 | 100’/200’ | 400' |

| 2700-300 | 3 | 3.5 | 7.0 | 150 | 2.19 | 100’/200’ | 400' |

| 2700-400 | 4 | 4.56 | 10.0 | 150 | 3.10 | 100’/200’ | 400' |

Series 2733 High-Flexibility Food Transfer Hose

Tube:

White chlorobutyl

Cover:

Gray synthetic rubber with external orange PVC helix

Reinforcement:

Multiple textile plies

Temperature Range:

-13 Deg. F. to 176 Deg. F.

Branding:

None

Application:

A new design for handling food, beverages, and other sanitary applications. Unique outer PVC rod helix allows the hose to glide easily across plant floors while providing excellent abrasion resistant qualities. 3-A chlorobutyl tube is contamination free and C.I.P. suitable. Extremely flexible for problem areas in the plant with crush resistant capabilities. Meets FDA and 3-A requirements.

| Part Number | I.D. (In) | O.D. (In) | Bend Radius (In) | W.P. (PSIG) | Vacuum Rating (In Hg) | Weight (Lbs/Ft) | Std. Length | Stock (Yes) or Min. Order |

|---|---|---|---|---|---|---|---|---|

| 2733-200 | 2 | 2.84 | 3.94 | 150 | 26.6 | 1.09 | 130' | Yes |

| 2733-250 | 2-1/2 | 3.39 | 5.12 | 150 | 23.6 | 1.32 | 130' | Yes |

| 2733-300 | 3 | 3.94 | 5.91 | 150 | 23.6 | 1.72 | 130' | Yes |

Series 2740 Bulk Material Discharge hose (3/16″ White tube)

Tube:

3/16” White natural rubber (FDA compliant)

Cover:

Gray, abrasion resistant SBR

Reinforcement:

Multiple textile plies w/dual static wire

Temperature Range:

-40 Deg. F. to 150 Deg. F.

Design Factor:

4:1

Branding:

Burgundy Mylar / White letters

Origin:

USA

Application:

Designed for in-plant and bulk transfer of flour, cake mixes and other abrasive foodstuffs. Series 2740 has a 3/16” white NR tube to resist abrasion and the dual anti-static wires can be electrically grounded to dissipate static charges.

| Part Number | I.D. (In) | O.D. (In) | W.P. (PSIG) | Weight (Lbs / Ft) | Std. Length | Stock (Yes) or Min. Order |

|---|---|---|---|---|---|---|

| 2740-400 | 4 | 4.56 | 40 | 2.08 | Yes | 400’ |

| 2740-500 | 5 | 5.56 | 30 | 2.46 | Yes | 400’ |

| 2740-600 | 6 | 6.56 | 25 | 3.04 | Yes | 400’ |

Series 2745 Bulk Food Material Handling Hose

Tube:

3/16” White natural rubber (FDA compliant)

Reinforcement:

Multiple textile plies w/dual wire helix

Cover:

Gray, corrugated natural rubber

Temperature Range:

-40 Deg. F. to 150 Deg. F.

Design Factor

4:1

Branding:

Burgundy Mylar / White letters

Origin:

USA

Application:

Used in tank truck and in-plant service to convey dry, non-oily abrasive materials such as sand, limestone, plastic pellets, etc. This hose is also designed to handle dry abrasive food products such as sugar, corn, etc. Recommended for conditions where extra lightweight, high flexibility and extreme bending is required under pressure, gravity flow or suction service. Not recommended for those materials where static electricity buildup is a problem.

| Part Number | I.D. (In) | O.D. (In) | Bend Radius (In) | W.P. (PSIG) | Weight (Lbs / Ft) | Std. Length | Stock (Yes) or Min. Order |

|---|---|---|---|---|---|---|---|

| 2745-300 | 3 | 3.75 | 6.0 | 100 | 2.13 | 100' | 400' |

| 2745-400 | 4 | 4.71 | 9.0 | 75 | 3.00 | 100' | 400' |

Series 2750 “Cobra” Corrugated Multi-Purpose Food Suction Hose

Tube:

White Nitrile

Reinforcement:

Multiple textile plies w/dual wire helix

Cover:

Corrugated gray Nitrile

Temperature Range:

-25 Deg. F. to 230 Deg. F.

Design Factor

4:1

Branding:

Blue Mylar / White letters

Origin:

USA

Application:

A lightweight, highly extremely flexible hose designed to handle a wide variety of both dry food and liquid transfer. The specially compounded tube is engineered to handle oily and non-oily products and is resistant to common CIP solutions. Manufactured on polished chrome mandrels, the mirror finish tube resists bacterial growth, while providing excellent flow rates. FDA/USDA compliant and conforms to 3-A Sanitary Standard 18-03.

| Part Number | I.D. (In) | O.D. (In) | Bend Radius (In) | W.P. (PSIG) | Vacuum (In Hg) | Weight (Lbs / Ft) | Std. Length | Stock (Yes) or Min. Order |

|---|---|---|---|---|---|---|---|---|

| 2750-150 | 1-1/2 | 1.94 | 2.5 | 150 | 29 | 0.81 | 100' | Yes |

| 2750-200 | 2 | 2.44 | 3.0 | 150 | 29 | 1.04 | 100' | Yes |

| 2750-250 | 2-1/2 | 3.01 | 5.0 | 150 | 29 | 1.51 | 100' | Yes |

| 2750-300 | 3 | 3.53 | 6.0 | 150 | 29 | 2.02 | 100' | Yes |

| 2750-400 | 4 | 4.55 | 7.0 | 150 | 29 | 2.69 | 100' | Yes |

Series 2760 Potable Water Hose

Tube:

White – Natural Rubber (FDA Compliant)

Cover:

Blue – SBR / EPDM Blend

Reinforcement:

Multiple textile plies

Temperature Range:

-40 Deg. F. to 180 Deg. F

Design Factor:

4:1

Branding:

Embossed

Applications:

Designed to handle water suitable for drinking. Used in oilfield or industrial applications, for discharge applications only. Compliant to FDA standards. Not NSF approved.

| Part Number | I.D. (In) | O.D. (In) | W.P. (PSI) | Weight (Lbs / Ft) | Std. Length | Stock (Yes) or Min. Order |

|---|---|---|---|---|---|---|

| 2760-050 | 1/2 | .80 | 250 | .23 | 100’ | 400’ |

| 2760-075 | 3/4 | 1.14 | 250 | .44 | 100’ | 400’ |

| 2760-100 | 1 | 1.49 | 250 | .55 | 100’ | 400’ |

| 2760-150 | 1- 1/2 | 1.98 | 200 | .77 | 100’ | 400’ |

| 2760-200 | 2 | 2.50 | 150 | .96 | 100’ | 400’ |

| 2760-300 | 3 | 3.58 | 150 | 1.72 | 100’ | 400’ |

| 2760-400 | 4 | 4.56 | 150 | 1.99 | 100’ | 400’ |

Series 2765 Premium Potable Water Hose

Tube:

Clear UHMWPE (Meets NSF-51 requirements)

Cover:

Smooth Blue EPDM

Reinforcement:

Multiple textile plies w/ monofilament helix

Temperature Range:

-40 Deg. F. to 212 Deg. F

Design Factor:

4:1

Branding:

White Mylar / Black letters

Origin:

USA

Application:

This premium hose is designed to handle water suitable for drinking in all industrial applications, deionized water, and high proof alcohol. The added features of the monofilament helix enhances vacuum rating, and the crush and kink resistance. FDA/USDA compliant.

| Part Number | I.D. (In) | O.D. (In) | W.P. (PSI) | Vacuum Rating (In Hg) | Weight (Lbs / Ft) | Std. Length | Stock (Yes) or Min. Order |

|---|---|---|---|---|---|---|---|

| 2765-075 | 3/4 | 1.27 | 200 | 30.0 | .42 | 100’ | 400’ |

| 2765-100 | 1 | 1.48 | 200 | 30.0 | .52 | 100’ | 400’ |

| 2765-150 | 1-1/2 | 2.07 | 200 | 30.0 | .90 | 100’ | 400’ |

| 2765-200 | 2 | 2.62 | 200 | 30.0 | 1.19 | 100’ | 400’ |

| 2765-250 | 2-1/2 | 3.01 | 200 | 30.0 | 1.39 | 100' | 400' |

Series 2770 Edible Oil Hose

Tube:

White NBR (FDA Approved)

Cover:

Gray NBR (FDA Approved)

Reinforcement:

Wire braid

Temperature:

0 Deg. F. to 275 Deg. F. … 350 Deg. F. Intermittent

Branding:

Embossed

Application:

Series 2770 is designed for the transfer of edible fluids, vegetable oils, salad dressings, vinegar, mustard, etc. The FDA approved tube will not impart taste. Excellent for service with hot oil fats and fryers.

| Part Number | I.D. (In) | O.D. (In) | W.P. (PSI) | Weight (Lbs / Ft) | Std. Length | Stock (Yes) or Min. Order |

|---|---|---|---|---|---|---|

| 2770-050 | 1/2 | 1.02 | 250 | .48 | 100’ | 1000’ |

| 2770-075 | 3/4 | 1.27 | 250 | .53 | 100’ | 1000’ |

| 2770-100 | 1 | 1.53 | 250 | .65 | 100’ | 1000’ |

Note: 200′ lengths available upon request.

Food & Beverage Hose

Food and beverage hoses are some of our best selling products for our distributors. Hose styles for the food and beverage industry have always been a focus for us. Unisource food and beverage hose is constructed using FDA grade materials. Our rubber hose with white food-grade liners rank with the industry’s finest. Vinyl/PVC hose specs with food-grade materials are our economical and light weight choice. The most severe food hose applications will involve elevated temperatures and/or easy-to-contaminate media. Our FEP lined rubber hoses are ideal for these situations. Unisource clear polyurethane hoses are ideal for abrasive food media, providing extended life and flexibility. Unisource is actively involved in the food industry and the with the various rules agencies. Ask about our food hose specs to meet 3-A, NSF 51, and USDA standards.

Unisource has food and beverage hose that meets industry standards where applicable. Typical references include:

- FDA Compliant

21 CFR 170-199 – The Food and Drug Administration (FDA) regulates food contact materials – materials intended to be in contact with food. These materials can be plastics, metal, paper, glass, additives, adhesives, inks, colorants, and coatings etc. During contact, molecules can migrate from these materials to the food and this FDA regulation is made to ensure food safety. 21 CFR 177.2600 – This FDA compliance, which falls under the above 21 CFR170 – 199, is concerned with indirect food additives, substances that may come into contact with food but are not intended to be added directly to food. Molecules from packing containers and food processing equipment such as food processing hose are examples of indirect food additives. CFR 21 FDA 177.2600 lists what materials are recognized as safe for food processing, how they should be cleansed prior to first use, and sets product extraction limits for aqueous and fatty foods.FDA Grade “A” Pasteurized Milk Ordinance (PMO) – is a set of minimum standards and requirements established by the FDA to regulate the production, processing and packaging of Grade A milk.

- USDA Compliant – The U.S. Department of Agriculture (USDA) regulates manufacturing, packaging, and handling practices in the agricultural food industry. USDA compliant products are documented as to their compliance with FDA food contact material standards by a written letter of guaranty from the manufacturer.

- NSF International, The Public Health and Safety Company™, a not-for-profit, non-governmental organization, is the world leader in standards development, product certification, education, and risk-management for public health and safety. NSF/ANSI-51, Food Equipment Materials establishes minimum health and sanitation requirements for materials used in the making of commercial food equipment and component parts. Materials cannot contaminate food nor make food equipment difficult to clean and sanitize. Fittings and tubes that comply with this standard are tested and approved by NSF for contact with potable beverages and foodstuffs.

These Standards are established by regulatory authorities to insure quality products are utilized in the production of food and drug products.

Contact your nearest Unisource location regarding our food and beverage hose line. Our Sanitary Hose line is a unique product set and is sold exclusively to our sanitary products distributors throughout North America. Contact us is you would like more information on our Sanitary Hose distribution program